Fungsi saka jinis catenary dijupuk mesin blasting

Fungsi saka jinis catenary dijupuk mesin blasting

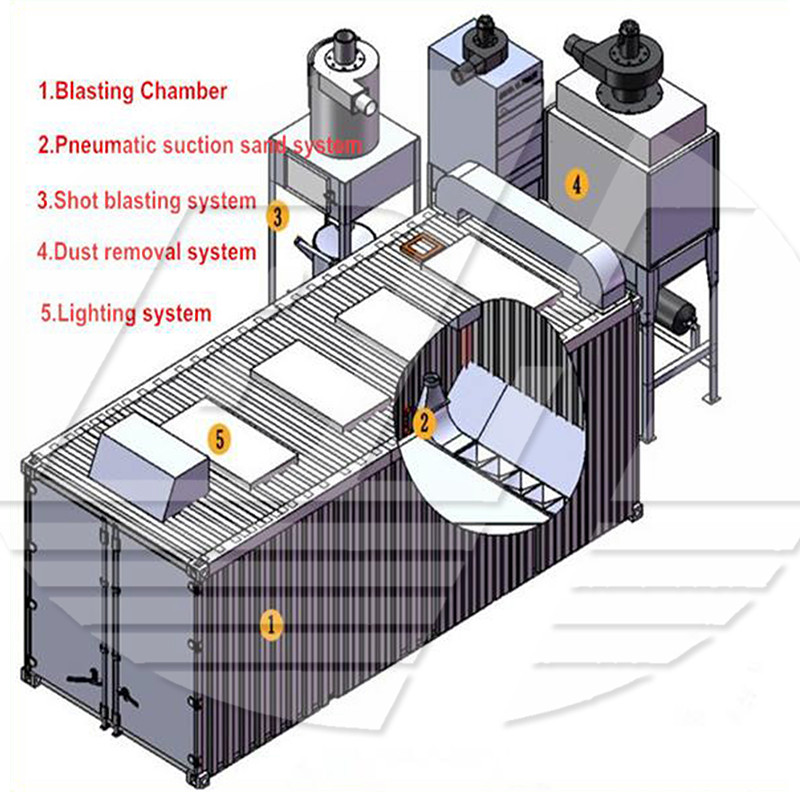

Q38, Q48, Q58 seri catenary stepping shot blasting machine digunakake kanggo mbusak castings, forgings, bagean struktural kayata workpiece lumahing wedhi, ukuran, teyeng lan ing.Lumahing workpiece katon luster metallic, lan castings cacat lumahing kapapar kanggo ngilangke kaku ing workpiece, roughness lumahing kanggo syarat Ra12.5 GB6060.5 syarat, ing baris karo tingkat JB / T8355-96 Sa2.5 nasional.

Spesifikasi model utama mesin penembak blasting tipe catenary

| Jinis | Volume pembersihan benda kerja (mm) | Laju aliran abrasif (kg / min) |

| Q383 | Φ 600 x 1400 | 4 x 260 |

| Q384 | Φ 800 x 1500 | 6 x 260 |

| Q385 | Φ 900 x 1400 | 4 x 260 |

| Q4810 | Φ 1000 x 1500 | 6 x 260 |

| paramèter | Q583 | Q585 | Q5810 | Q588 | |

| ukuran workpiece reresik | mm | 800 x1500 | 800 x1200 | 1300 x 2800 | 550 x2200 |

| nomer pancing | Setel | 2 | 4 | 6 | 4 |

| nomer blaster | kg | 4 | 6 | 6 | 4 |

| laju aliran abrasif | kg/min | 4 x250 | 6 x360 | 6 x330 | 4 x480 |

| daya saka blaster | kw | 4 x15 | 6 x22 | 6x22 | 4 x22 |

| max.bobot saka Crane mbukak | kg | 300 | 500 | 1000 | 800 |

| kapasitas saben pancing | h | 40 | 55 | 50 | 30 |

| ukuran kamar cleaning | mm | 3062 x 1800 x 2800 | 8500x1800x3885 | 8500x2300x4800 | 6800x2600x3325 |

| volume udara total | m³ / jam | 15000 | 18000 | 18000 | 17200 |

| daya total | kw | 74.5 | 186.85 | 186.85 | 121.05 |

Jenis Catenary Shot Blasting Machine Aplikasi:

Casting wesi resik

Casting baja resik

Clean Forging

bagean Stamping resik

Silinder LPG resik

Logam jinis liyane kanthi efisiensi reresik sing gedhe banget

Fitur mesin blasting jinis Catenary

Ngapikake resistance lemes lan anti-kelelahan

Copot wedhi saka lumahing logam

Nambah urip layanan

Mbusak karat logam

Copot kulit oksida permukaan logam

Nggawe permukaan nuduhake luster logam.

Nambah daya adesif sadurunge lukisan

Ngilangi stres internal

Fitur Utama

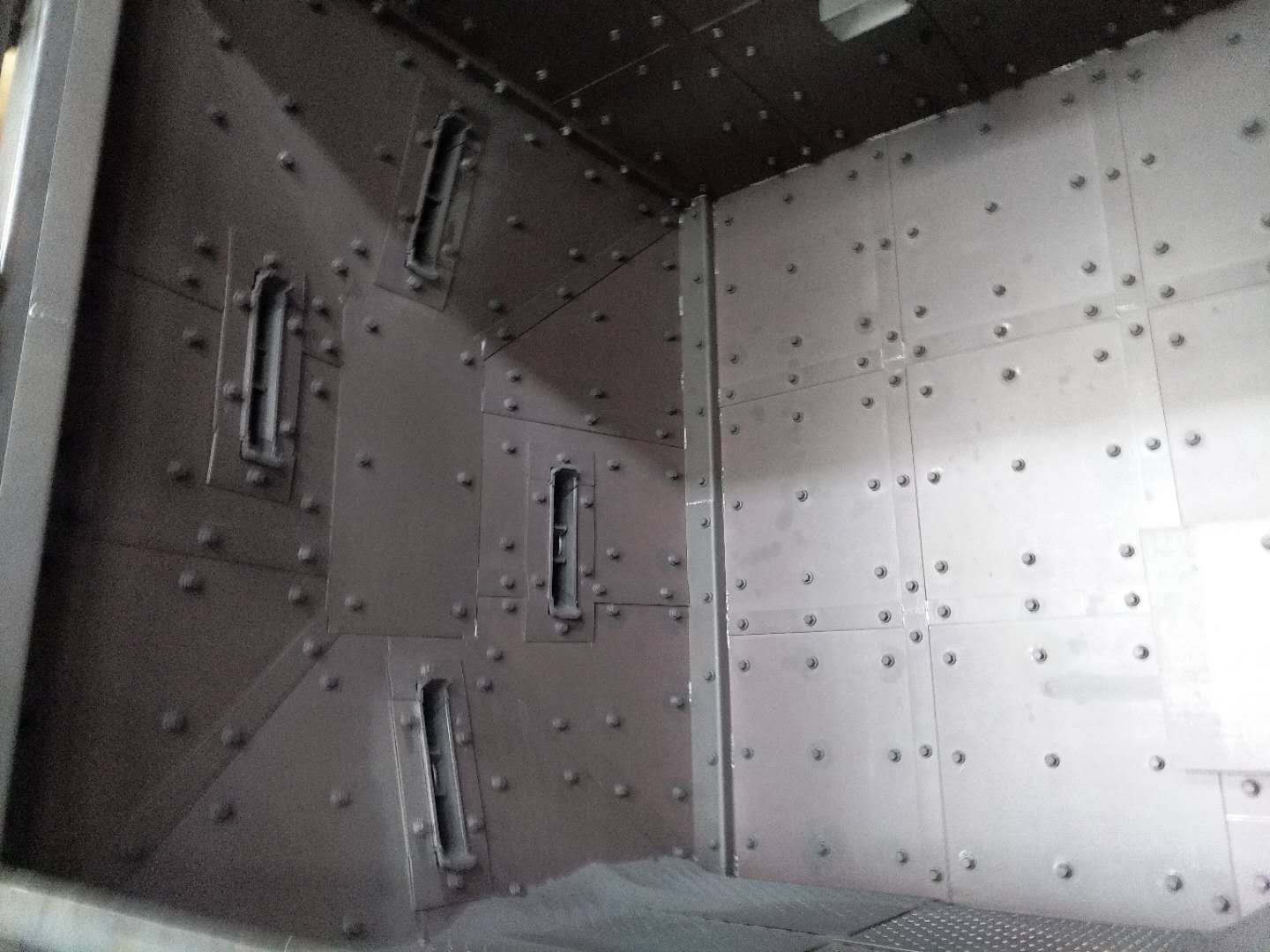

1) Rolling manganese 13 papan nglindhungi, 8000-10000 jam wektu urip maneh.

2) Lurus utawa Y wangun trek conveyor, loading kapasitas 500-50000kg

3) Kacepetan reresik dhuwur lan ngirit tenaga kerja.

4) spare parts turbin kabeh krom dhuwur

5) struktur kompak lan kuwat

6) konsentrasi bledug kurang saka 80mg/m3

7) bisa nggunakake motor ABB, SEW reducer, bantalan SKF

8) paket: kothak kayu kanggo kabinet kontrol

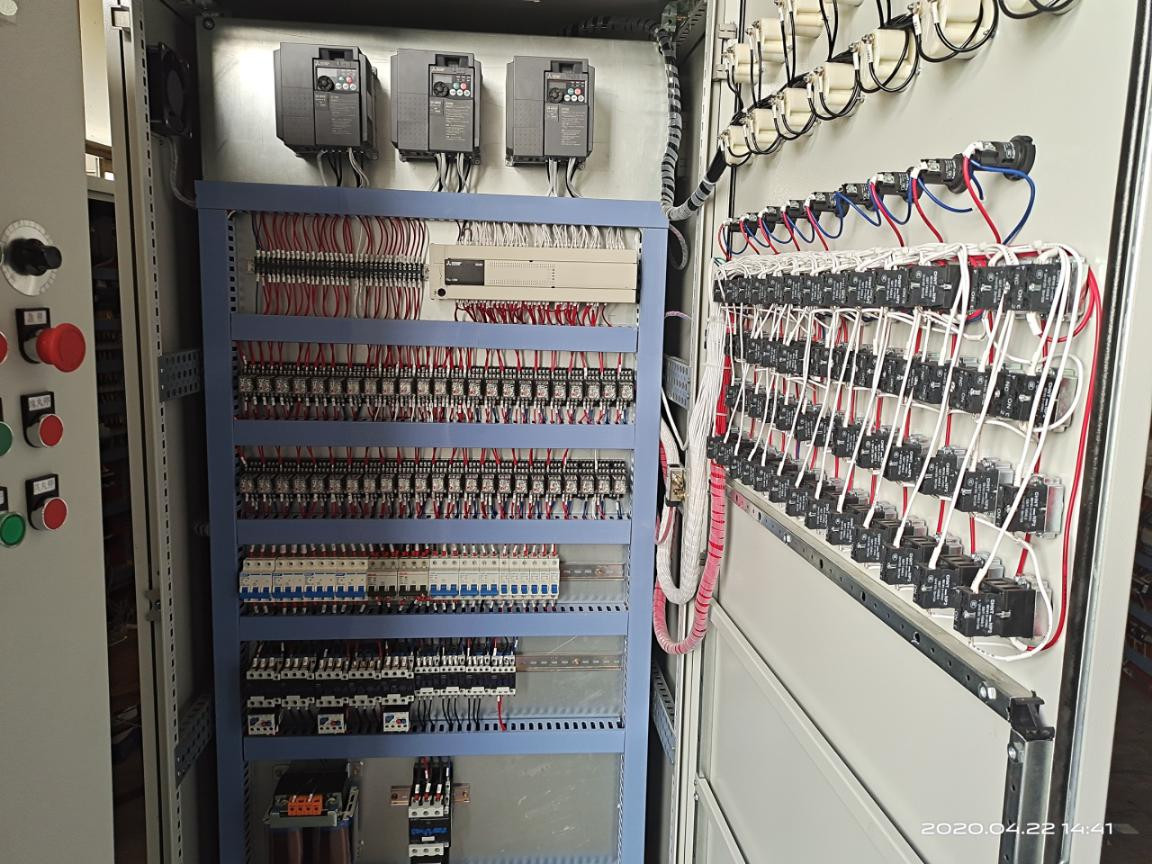

9) Sistem kontrol PLC (Siemens utawa Omron utawa Mitsubishi), lan nyetel parameter lan keamanan

10) Sistem sirkulasi projectile nggunakake piranti ngawasi aktif.Nalika sawetara bagean ora mlaku kanthi lancar utawa macet, bakal aktif weker lan menehi kabar marang bagean sing rusak, sing trep kanggo ndandani target.

11) Workpieces bisa di resiki nalika mlaku-mlaku, utawa lumaku sawise reresik, etc., karo tingkat dhuwur saka inisiatif, nemen ngurangi kakiyatan pegawe buruh

10) wektu pangiriman: ing 5 dina kanggo jinis standar, liyane biasane 15-60 dina apa

Apa dokumen sing diwenehake?

1.Instruction manual ing Cina lan Inggris.Isine

Lay-out drawing, Lay out drawing bakal diwenehake sajrone sewulan sawise kontrak aktif.

Operasi, pangopènan lan instruksi lubricating

Skema listrik

Dhaptar spare parts dianjurake karo prices

Dokumentasi komponen standar

2. Bill of loading, daftar pilihan, sertifikat asal

3.Engineer bisa menyang papan bantuan kanggo instalasi